Andrew Kness and Erika Crowl

University of Maryland Extension

Drones are becoming increasingly popular in agriculture for not only imagery, but product application. As a result, startup companies offering aerial pesticide application via drone are emerging. Farmers have taken interest in the technology and service for several reasons, but the main benefit to using a drone to apply crop production products in soybean and corn is that it offers a feasible method for in-season foliar product application to fields that are smaller, fragmented, or irregularly shaped, without the potential for damaging the crop with a ground spray rig. Additionally, drones may have an advantage over helicopters or fixed-winged aircraft in small fields because they are more nimble and have the potential to achieve application to field edges that would be missed by aircraft. Finally, drones are much less intrusive to curious neighbors who often raise concerns when they see an aircraft applying products to fields.

Drones are becoming increasingly popular in agriculture for not only imagery, but product application. As a result, startup companies offering aerial pesticide application via drone are emerging. Farmers have taken interest in the technology and service for several reasons, but the main benefit to using a drone to apply crop production products in soybean and corn is that it offers a feasible method for in-season foliar product application to fields that are smaller, fragmented, or irregularly shaped, without the potential for damaging the crop with a ground spray rig. Additionally, drones may have an advantage over helicopters or fixed-winged aircraft in small fields because they are more nimble and have the potential to achieve application to field edges that would be missed by aircraft. Finally, drones are much less intrusive to curious neighbors who often raise concerns when they see an aircraft applying products to fields.

Although drones offer a lot of potential, there is very little published data on their efficacy to apply products, which is cause for question and concern as to if drones are a viable and worthwhile means of applying products, such as pesticides, to corn and soybeans. Additionally, drones tend to lack spray tank capacity, so spray volumes with drone applications are low (1-2 gallons per acre). These low-volumes may pose challenges in achieving adequate coverage; however, products are applied at a greater concentration. This research project, funded by the Maryland Soybean Board, aims to collect data regarding drone spray efficacy in corn and soybean.

Methods

Two different drones (Figure 1) were used to apply water to standing corn and soybeans in fields located in Harford County, Maryland on August 27, 2020. Corn was planted on 30-inch rows and at the R4 growth stage during application. Full season soybeans were planted on 15-inch rows and at R6 during application.

The drones were operated by certified pilots who offer custom pesticide application in field crop and nurseries. Weather conditions were sunny and 91°F with variable winds out of the Northeast at 5 mph, gusting to 25 mph.

Prior to spraying, water-sensitive cards (Syngenta AG®, Basel, Switzerland) were placed within the crop canopy at various heights in sets of five replicates. Three heights were used for both corn (top: third leaf from tassel; middle: ear leaf; and bottom: third leaf from bottom) and soybean (top: upper most fully expanded leaf; mid: middle of canopy; and bottom; 1 foot up from soil). When water droplets hit the card, the card arrests the spread of the droplet and stains the card blue. The cards were retrieved then scanned into the computer and analyzed using the software DepositScan (USDA-ARS, Wooster, OH), which calculates percent spray coverage, droplet density, and droplet size.

Each drone applicator flew on water at approximately 4 feet above the canopy at 16 mph onto corn and soybeans at a rate of 1 gallon per acre for Drone 1 and 1.5 gallons per acre for Drone 2 using TeeJet® TXA8002VK nozzles.

Results & Discussion

Due to the extremely high humidity, close canopy, and transpiration rate of the soybean plants, the middle and bottom spray cards in the soybean plots were difficult to read. As a result, data for bottom soybean cards were omitted.

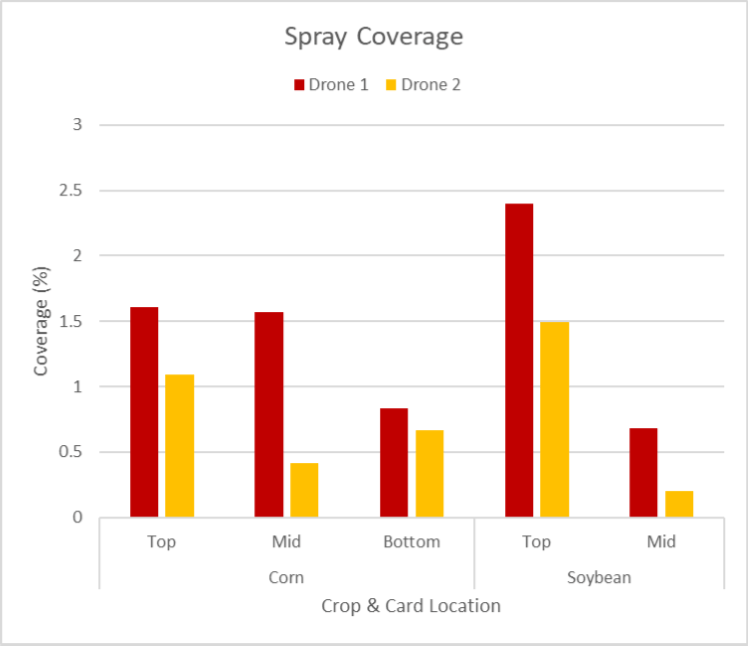

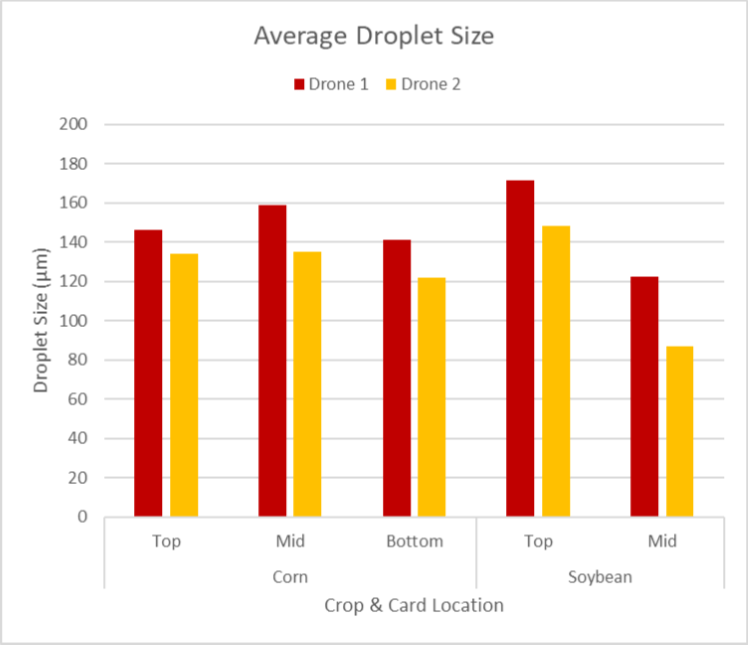

As to be expected, spray coverage was highest in the top of the canopy for both corn and soybean for both drones (Figure 2). Drone 1 achieved 1.61% and 2.40% coverage in the top canopy of corn and soybean respectively. Drone 2 also achieved greater coverage in the top canopy of soybean (1.50%) than corn (1.10%). Both drones delivered nearly identical droplet density (Figure 3) in the top canopy of both corn (18.9 drops/cm2) and soybean (22.0 drops/cm2). Droplet size (Figure 4) in the top canopy of corn for Drone 1 was 146 µm vs. 134 µm for Drone 2 and 171 µm for Drone 1 vs 148 µm for Drone 2 in soybean top canopy.

Spray coverage dropped only slightly for Drone 1 (to 1.57%) in corn from top to middle, but much more in soybean (down to 0.68%), likely due to the dense canopy. Coverage dropped to 0.42% for Drone 2 at the ear leaf in corn and down to 0.20% in the mid canopy soybean. Drone 1 achieved 21.65 drops/cm2 for the ear leaf in corn whereas Drone 2 delivered 7.00 drops/cm2. In mid canopy soybean, droplet density was similar for both drones (13.5 drops/cm2 for Drone 1 and 10.17 drops/cm2 for Drone 2). Droplet size for both drones were similar between top, middle, and bottom corn. Droplet size decreased for both drones in middle canopy soybean to 122 µm for Drone 1 and 87 µm for Drone 2.

Spray coverage and droplet density were similar for both drones in bottom canopy corn. Spray cards for bottom canopy soybeans were not analyzed due to artifacts created by canopy humidity.

It is generally recommended that droplet density should be between 20-30 droplets/cm2 for adequate insecticide application, between 20-40 droplets/cm2 for herbicide application, and at least 50 droplets/cm2 for fungicide applications. Based on these assumptions, both Drones have the capability to deliver densities at or over 20 droplets/cm2 in the upper canopy, which may be adequate for herbicide or insecticide applications. However, a greater density of droplets needs to be achieved for adequate fungicide application. Previous research has shown that flight velocity plays a significant role in droplet density and spray coverage (Hunter III et. al., 2020). Spraying slower would likely improve coverage and efficacy of fungicides applied via drones, which will be an area of future research for this project.

Example Spray Card Images (click to enlarge)

Acknowledgements

We would like to thank the Maryland Soybean Board for funding this research, A1-Aerials, K Drone, and Crowl Brothers, Inc. for collaborating on this research project.

Literature Cited

Hunter JE III, Gannon TW, Richardson RJ, Yelverton FH, Leon RG (2020) Coverage and drift potential associated with nozzle and speed selection for herbicide applications using an unmanned aerial sprayer. Weed Technol. 34: 235–240. doi: 10.1017/ wet.2019.101